DLP is a technology commonly used in 3D printing, including for creating jewelry models. Here’s a brief overview of our work with DLP Technologies :

-

DLP Technology:

- DLP is a type of 3D printing technology that uses light to cure or harden a liquid resin layer by layer.

- In the context of jewelry manufacturing, DLP 3D printers can be used to create highly detailed and intricate models with high resolution.

-

CAM in Jewelry Making:

- CAM refers to the use of computers to aid in the manufacturing process. In jewelry making, CAM is often used in conjunction with CAD (Computer-Aided Design) to create digital models of jewelry.

-

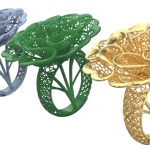

Creating Jewelry Models with DLP:

- Jewelry designers often use CAD software to create digital models of their designs.

- These digital models can then be converted into a format suitable for 3D printing.

- DLP 3D printers use a liquid resin that is selectively cured by light, layer by layer, until the final 3D object is created.

-

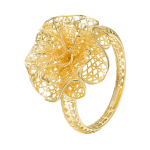

Applications in the Jewelry Industry:

- DLP technology is popular in the jewelry industry because it allows for the production of highly detailed and intricate designs that may be challenging or impossible to achieve with traditional methods.

-

Post-Processing:

- After printing, the 3D printed jewelry model may require post-processing, which can include tasks like cleaning, curing, and polishing to achieve the desired final result.

-

Materials:

- The choice of materials for DLP printing in jewelry making includes various resins that offer different characteristics such as clarity, flexibility, or durability.

From our facility you can make your product with full customization and 100% guarantee with proper agreement.